Index

Other categories

28 May 2018

MagWare helps you to manage your current WMS

Rewix uses MagWare to manage your e commerce warehouse by taking advantage of the most advanced features.

Magware is theWMS (Warehouse Management System) software made by Re-Store and used in the most important logistics of Italy. It is the fashion logistics software of DHL SCM.

What is MagWare

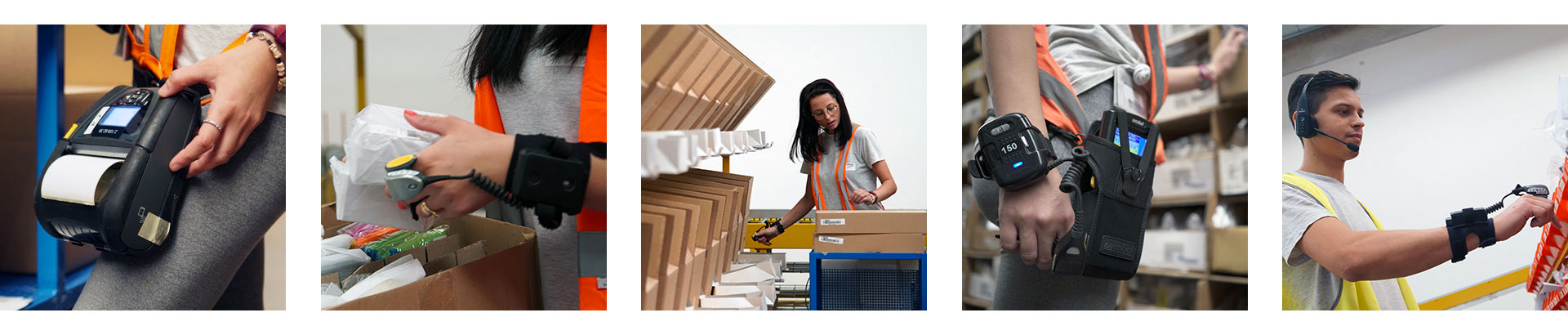

MagWare is a warehouse management and commerce system designed to facilitate the activities of dedicated warehouse resources.

Managing a physical warehouse requires the repetition of actions to manipulate goods. MagWare simplifies all warehouse management operations while avoiding wasted operator time and energy.

All the main functions of MagWare are made to be performed in real time by radio terminals with other systems such as thin clients, voice guidance(MagWare Voicering) and automated systems. The majority of warehouse tasks can be performed with them.

Some warehouse tasks such as ticking and packing can be performed more easily on special workbenches: in these cases, the MagWare Desk application is available that allows these tasks to be performed while taking advantage of a larger, more functional screen.

Office work, on the other hand, is carried out on PCs or thin clients through the MagWare Control Center application, which allows in and out document entry and management, production of printouts and data extractions, and supervision and control of the entire system.

For the management of automated machines, specific applications are available for interfacing with automatic weighing and marking systems, sorters, AS/RS, traslo, etc.

MagWare consists of a computer system that best suits your material handling needs.

MagWare is designed in several functional versions, each dedicated to a particular area of use.

MagWare for fashion e commerce

MagWare Fashion was designed specifically to simplify logistics for companies operating in the apparel industry.

Among the main functions implemented specifically for apparel:

- Size management and size scales

- Logical and/or physical warehouse management separated by first line, available, foul, second choice, etc

- Finished goods and raw materials management

- Quality control management

- Hanging and hanging garment management

- Management to technical box or customer box

- Management of loading units and multi SKU leases, including in storage

- Samples management

- Advanced returns management

- Relabeling functions

- Management of value-added activities (packaging, ironing, repair, etc.)

- Integration with RFID systems for anti-counterfeiting and parallel market control

- Visual picking function for stockists, internal use, sampling, etc

- Footwear box and assortment management

- Bubble and packing list printing with size scale

- Bubble and/or packing list printing with automatic insertion in shipping parcel

Features of MagWare

Using a sophisticated resource scheduling and control system, MagWare coordinates and optimizes all the activities necessary to manage a warehouse, from the entry to the exit of goods.

The phases of goods management of a warehouse, are: receiving, allocation and storage, picking, packing, shipping, inventories and adjustments.

MagWare automates each activity and makes the work of dedicated warehouse operators easier.

Reception

- Management of delivery reservations at the depot with recording of courier delivery date, expected quantities, etc

- Management of checkin and unloading of booked goods by radio terminal and temporary allocation of received units awaiting receipt (staging)

- Management of pre or post receipt quality control procedures

- Incoming documents (ddt, packing list, ASN) that can be entered manually or imported from customer or supplier management system

- Complete purchase order management (importable from host) and feedback and verification upon receipt of goods

- Support in all receiving modes for different types of UdC: boxes, baskets, pallets, hanging carts, etc.

- Ability to split the load of a document into multiple receiving operations to divide the workload over multiple operators

- Receipt by fixed workstation and barcode guns (Tick Counter) or by radio terminal

- Reception with piece-by-piece barcode ticking (full ticking)

- Receipt with barcode reading of a SKU and manual quantity entry

- Receipt without reading any barcode (manual SKU and quantity entry)

- Receipt without counting, made according to the data contained in the incoming packing list and with only the application of the internal warehouse UdC barcode on the UdCs

Allocation and storage

- Storage of goods by radio terminal with control of storage location by barcode reading

- Possibility to leave the operator free to choose the storage location, to suggest to the operator a non-mandatory location or to force the operator to store in the location imposed by the system

- Calculation of the storage location decided by the system according to different and parametric logics (FIFO on entry date, product type, UdC type, rotation speed, UdC composition, etc.).

- Storage at loading units or pouring into pre-existing UdCs (compacting to storage)

- Possibility of control and integration with automatic conveying and storage systems such as roller conveyors, stacker cranes, automatic warehouse, etc

- Load data transmission to management upon completion of receipt or upon placement of the leased goods (goods available)

Withdrawal

- Creation of fulfillment batches according to various parameters, customizable for each agent/customer

- Creation of optimized picking missions, as desired, based on: optimal route, commodity constraints, picking facility/equipment constraints

- Rule-driven workflow (batch) planning that determines how picking tasks will be accomplished

- Ability to create automatic batches upon receipt of orders fulfillment and automatic dispatch of activities to pickers (real-time warehouse for e-commerce)

- Picking by radio terminals

- Order picking (single pick) with or without Pick&Pack

- Cluster picking (picking several simultaneous orders) with or without Pick&Pack

- Simple zone picking with or without Pick&Pack

- Batch picking (massive)

- Picking by paper list:

- Order picking without Pick&Pack

- Cluster picking (multiple simultaneous order picking) without Pick&Pack

- Batch picking (massive)

- Possibility of control and integration with automatic sorting or picking systems, such as pick-to-light systems, sorters, cluster picking trolleys, carousels, lift-transfer warehouses, AR/SR systems, etc

- Automatic printing of transport documents at the end of picking (Pick&Pack) for insertion in last order package (barcode reading on document)

Packaging

- Packing and marking by fixed stations and barcode guns

- Parcel composition by item-by-item ticking (for pickups without Pick&Pack)

- Manual parcel weight entry or automatic reading by interfacing with electronic scales

- Shipping label production by label printer according to the specifications of the courier used

- Cardboard packing list label production by label printer or overall packing list by laser printer

- Automatic packing list labeling by weighing station and automatic printing

- Automatic printing and application of shipping label according to specifications of the carrier used

- Automatic printing and application of carton packing list label (it is also possible to print and apply a single label showing both shipping data and package contents

Shipment

- Creation of shipping bills by carrier, geographic area, zones and delivery routes -

- Setup and control of shipment component UdCs using radio terminals

- Billing by single order or massive for all orders included in a shipment, with automatic production of multiple copies (1 copy, 2 copies, 2 + 1 copies) if laser printer is used

- Automatic copy production of bills in PDF format and sending via email or FTP to host or commodity destination

- Printing of packing list (waybill, burgundy) for the vehicle/courier at the time of pickup, showing delivery date/time, bills included, number of packages, weights, volumes, delivery notes, etc.

- Automatic document and file creation for information systems provided by the carrier (optional modules for major carriers such as TNT, UPS, Bartolini, DHL, etc.)

Inventories and adjustments

- Annual, end-of-season, rotating and sample inventories, all executable via radio terminals with full ticking of location, UdC and contents via barcode

- Automatic production of adjustment movements following inventory activities

- Automatic production of opening accounting movements for annual or seasonal inventories

- Automatic recording and consultation of opening, loading, unloading and adjustment movements with the possibility of establishing current and historical stock (warehouse journal)

Other functions

- Bulk or UdC merchandise movement activity using radio terminal, with the ability to change storage rules and have the system reapply them to perform guided reorganization of the warehouse in accordance with the new arrangements

- System-driven merchandise recompacting activities via radio terminal

- Support for printing custom (retail) item labels that can be printed and applied at receiving or picking/packing (Note: requires customization to receive the necessary data from the information system).

- All prints, reports and labels are fully customizable in content, format and layout and can include graphics such as logos, trademarks, etc. Customization can also be done by the customer without Restore's intervention using the Sybase Infomaker reporting program (not included in the license).

Discover MagWare integrated with Rewix e commerce platform for your online store: all the essential tasks to better manage your shop!